Hydroscand ORFS-Coupling

Hydroscand

Product Description

Product Group 770/510

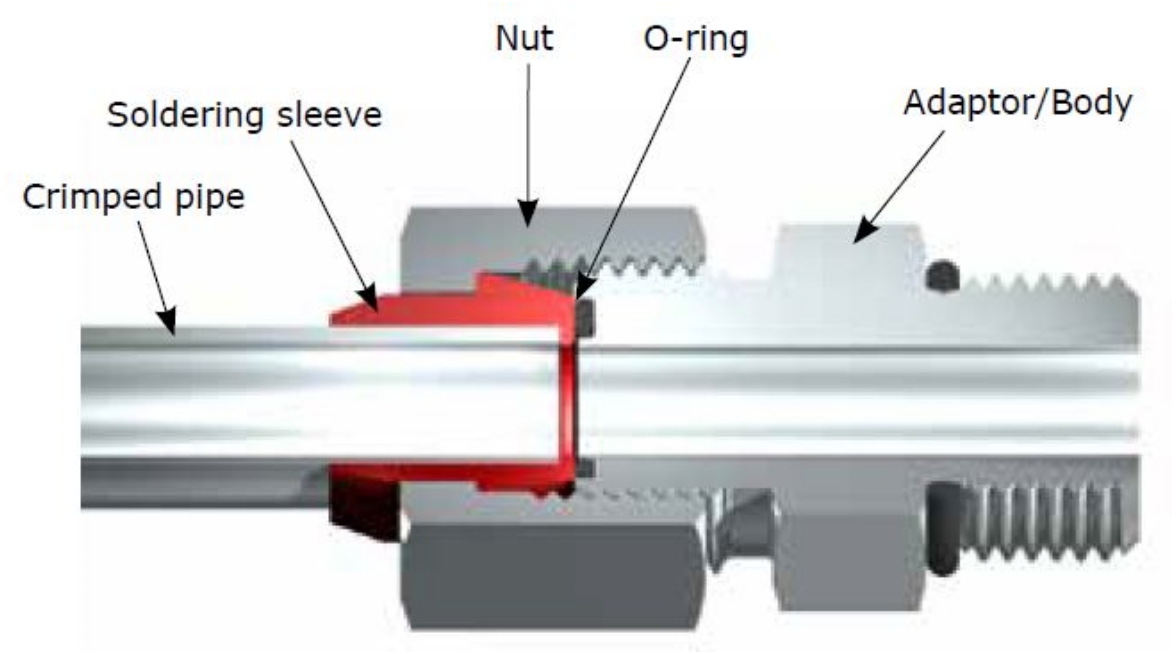

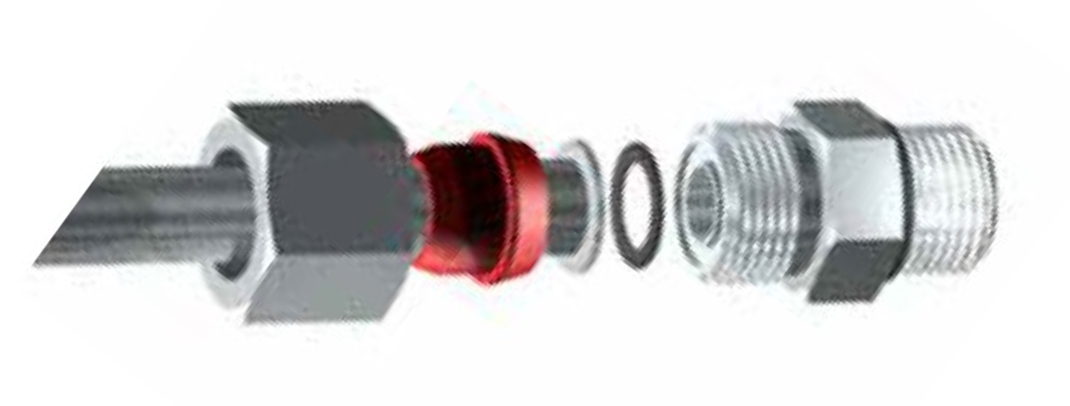

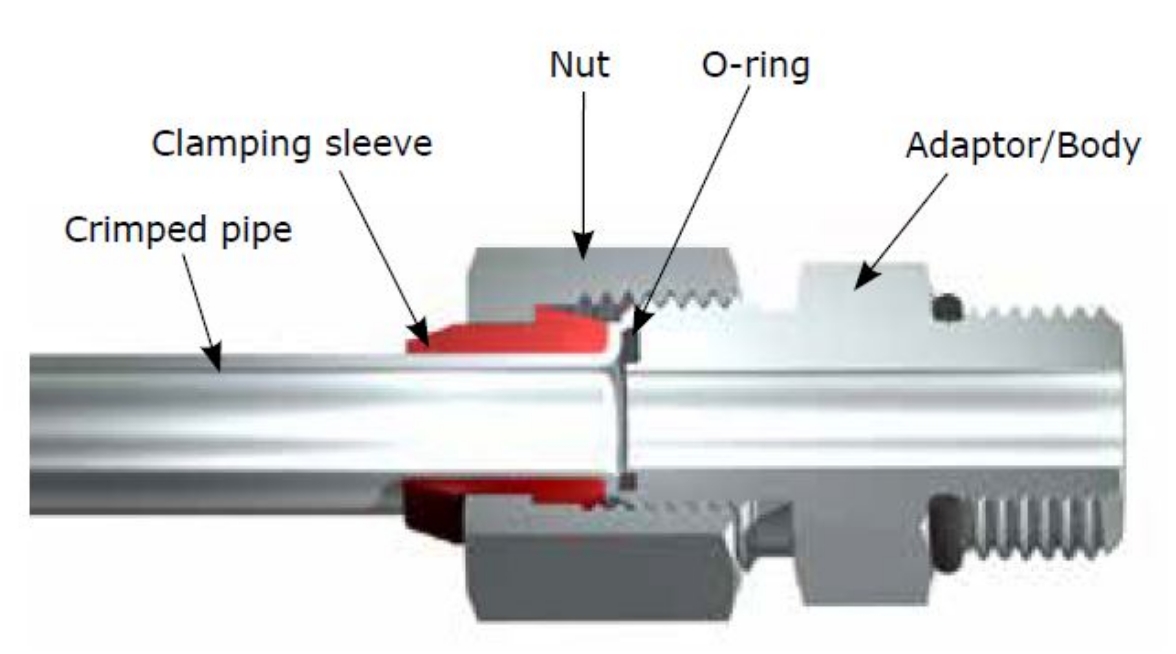

Our ORFS couplings are equivalent to SAE J1453 and ISO 8434-3.The couplings handle high pressure up to 63.0 MPa, with a safety factor of 1:4. They are also resistant to vibrations and system impulses. The sealing between pipe and adaptor is created by a O-ring, which gives a safe unit. The coupling can be dismantled and assembled multiple times without deterioration of the unit. The only thing that needs to be changed is the O-ring. Compared to other types of steel pipe couplings, the ORFS coupling is very resistant to over-torque. This makes a correct assembling easier, even for untrained persons. Changing the clamping sleeve, the coupling can be used for both metric & inch pipes.

Part numbers

The ORFS coupling part number consists of two parts. The first four digits signify the type (compare with the flare fittings) The four last digits signify the recommended pipe size in inches. 1/4” for example, gives part number 04. For deviating connections, the thread size is given in the part number, for example G 3/8” = 06.

Pipe OD | Thread UN | Part No. |

|---|---|---|

| 1/2" | 9/16" - 18 UNF | 04 |

| 8m, 5/16" 10mm, 3/8" | 11/16" - 16 UNF 11/16" - 16 UNF | 06 06 |

| 12mm, 1/2" | 13/16" - 16 UNF | 08 |

| 14mm 15mm 16mm, 5/8" | 1" - 14 UNF | 10 10 10 |

| 18mm, 3/4" 20mm | 1 3/16" - 12 UNF | 12 12 |

| 22mm, 7/8" 25mm, 1" | 1 7/16" - 12 UNF 1 7/16" - 12 UNF | 16 16 |

| 28mm 30mm 32mm, 1 1/4" | 1 11/16" - 12 UNF | 20 20 20 |

| 35mm 38mm, 1 1/2" | 2" - 12 UNF | 24 24 |

Assembly Instructions

1.Lubrication: Lubricate the O-ring before assembly. On couplings in steel, the threads do not need lubrication. On couplings in stainless steel, the threads should be lubricated to not cut. Use recommended lubricant part.no 5650-00-05.

2.Assembly: Screw the nut on the body. Tighten the nut until metal contact is obtained Mark on body and nut. Then tighten the nut according to the table below.

Flanging

Cut the pipe so the flange is 90º. The clamping sleeve in combination with the nut and O-ring seal the unit.

Brazing

An alternative to cut the pipe is to braze/weld an ORFS sleeve to the pipe.