Hydroscand Cutting Ring Fittings

Hydroscand

Product Description

Product Group 600

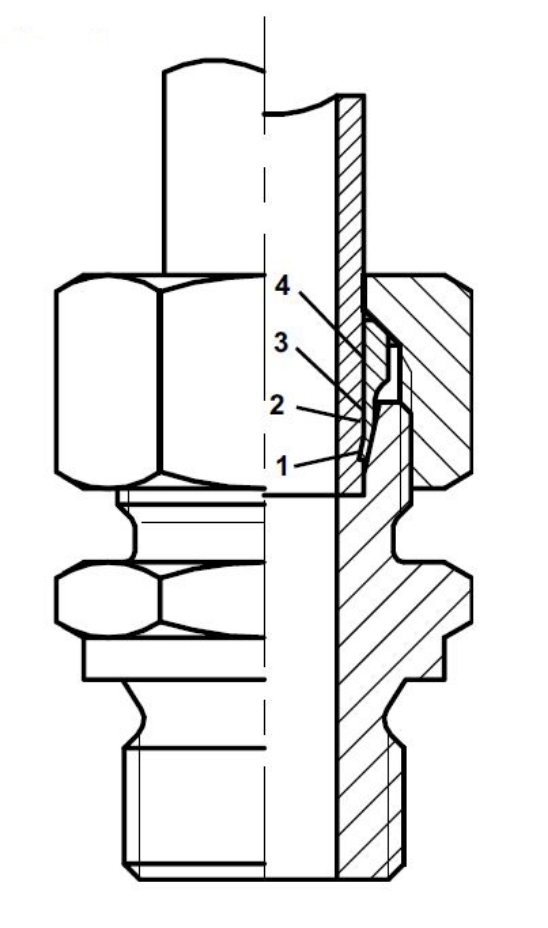

Mammoth’s cutting ring fittings are used for tubing, mainly in hydraulic and pneumatic applications. Mammoth can also offer a stainless steel cutting ring fitting designed for aggressive media and surroundings. Working pressure/PN up to 63 MPa/630 Bar, for male pipes of 4–42 mm diameter. Pressure ratings according to ISO 8434-1. Cutting ring fittings are characterised by a very rigid tube assembling, resistance to vibrations and pressure impulses. The fittings can be dismantled/reassembled more than once. When assembling the cutting ring fitting, the ring’s two edges are pressed into the pipe, which gives a mechanical bearing. The first edge has already started the penetration before the second edge starts cutting into the pipe. After the assembling, part three of the cutting ring is pushed in between the cone and the pipe, to make sure no vibrations are transported to the cutting edges. The fourth part secures radial movement. The design of the ring profile gives a very strong, axial and radial bearing. The tension is carried by the whole cutting ring length.

Materials

Mammoth’s cutting ring fittings are manufactured of automatic steel or of forged materials. The standard surface treatment is E-coated. E-coated is the name of the surface treatment Mammoth use for its fittings. It is Cr6 free and therefore more environmentally friendly and better for human health. Temperatures up to +200°C. Sealing with standard NBR maximum +90°C.

CONNECTIONS

Whitworth pipe thread G, cone pipe threads R, NPTF cone, UNF, metric. Cutting ring cone according to ISO 8434-1.

CERTIFICATIONS

Mammoth can deliver fittings with the following standards/certificates: DVGW, Norske Veritas, Germanischer Lloyd, ISO 9002.

Assembly Instructions

1.Cut the tube at a 90 degree angle (do not use roller, type tube cutters), remove all internal and external burrs.

2.Oil the 24°cone, the thread of the fitting body, the cutting ring and the nut. For carbon steel fittings, use mineral oil. For stainless steel fittings, use Mammoths special oil, part number 5650-00-05.

3.Fit the nut and the cutting ring on the tubes as shown. The larger diameter of the cutting ring must face the nut.

4.Insert the tube on the 24°cone until it comes into contact with the stop. Tighten the nut by hand until the cutting ring rest firmly on the nut. Then tighten the nut with a wrench until the cutting edge of the ring is in contact with the tube and prevents rotation if this.

5.Holding the tube against its stop and making sure it does not rotate, tighten the nut by 3/4 of a turn. This way, the cutting ring cut into the outer part of the tube for the necessary depth and raises an edge in front of its cutting edge while the second cutting edge clinches the tube at the same time.

6.Loosen the nut and check that there is a clearly raised edge all round the tube. The edge must cover 80% of the front of the cutting ring. This check is peremptory for the safety of all concerned. If the raised edge is not satisfactory, pre-assembly must be repeated. The cutting ring can rotate on the tube. This is normal and does not affect the density.

7.Final assembly. Reassemble the nut on the fitting until a certain resistance is encountered and then tighten for a further 1/4 turn.

Final assembly of pre-assembled fittings

Screw the nut by hand as hard as you can, then the nut should be tightened approximately 1/2–3/4 turn more. This information apply to all our pre-installed fittings All the pre-assembly of stainless steel fittings must be performed with a pre-assembly tool (blocks or machines). For best results, use Mammoths special oil, part number 5650-00-05.